AFA Cooper offers a wide range of solutions to help your production line improve overall operating efficiency. Please see our list of solutions that AFA Cooper currently offers.

Bag Machines

Seal and perforate bags up to 100″ thick or thin guage. Ideal for sealing multiple lanes of bags or running wide and long industrial bags.

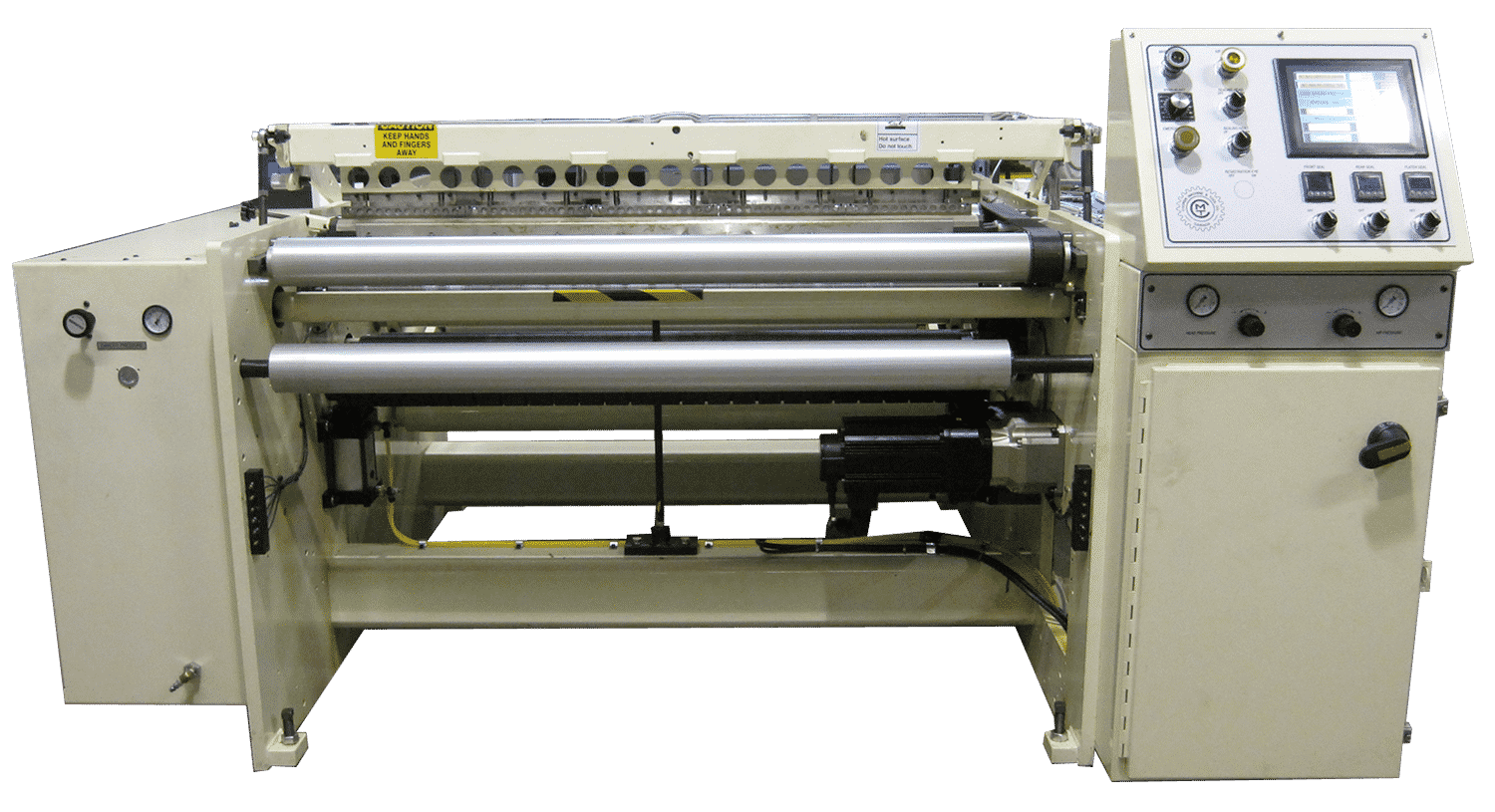

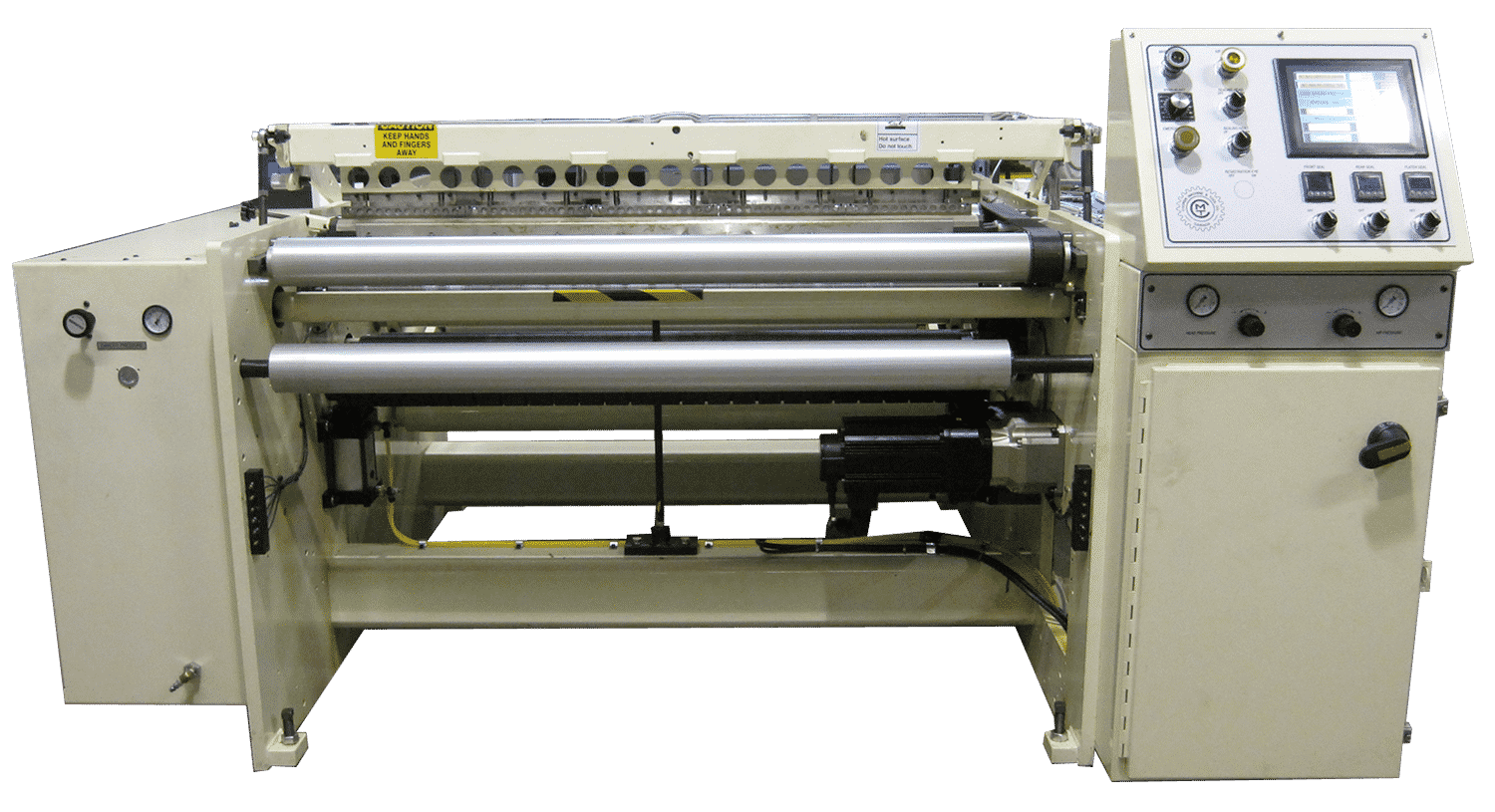

Bottom Seal – Hydraulic

The Bag Machine is a bottom seal shuttle continuous operation machine. It can seal and perforate bags up to 100″ (2540mm) wide, thick or thin guage; ideal for sealing multiple lanes of bags or running wide and long industrial bags.

Bottom Seal – Servo

The Bag Machine is a bottom seal shuttle continuous operation machine. It can seal and perforate bags up to 100″ (2540mm) wide, thick or thin guage; ideal for sealing multiple lanes of bags or running wide and long industrial bags.

Winders

Our various winder models feature automatic roll changes, automatic indexing, automatic fly cutter cut off, and various arrangements for sheeting.

Budget Winder

The smaller and simpler Budget Winder with a manual roll change is suitable for short run and small diameter rolls.

Core/Coreless Winder

Our Core/Coreless Winders operates at high speeds up to 400 ft/min, counts the number of clear or printed bags in various sizes, and automatically roll changes up to 10 roll changes/min.

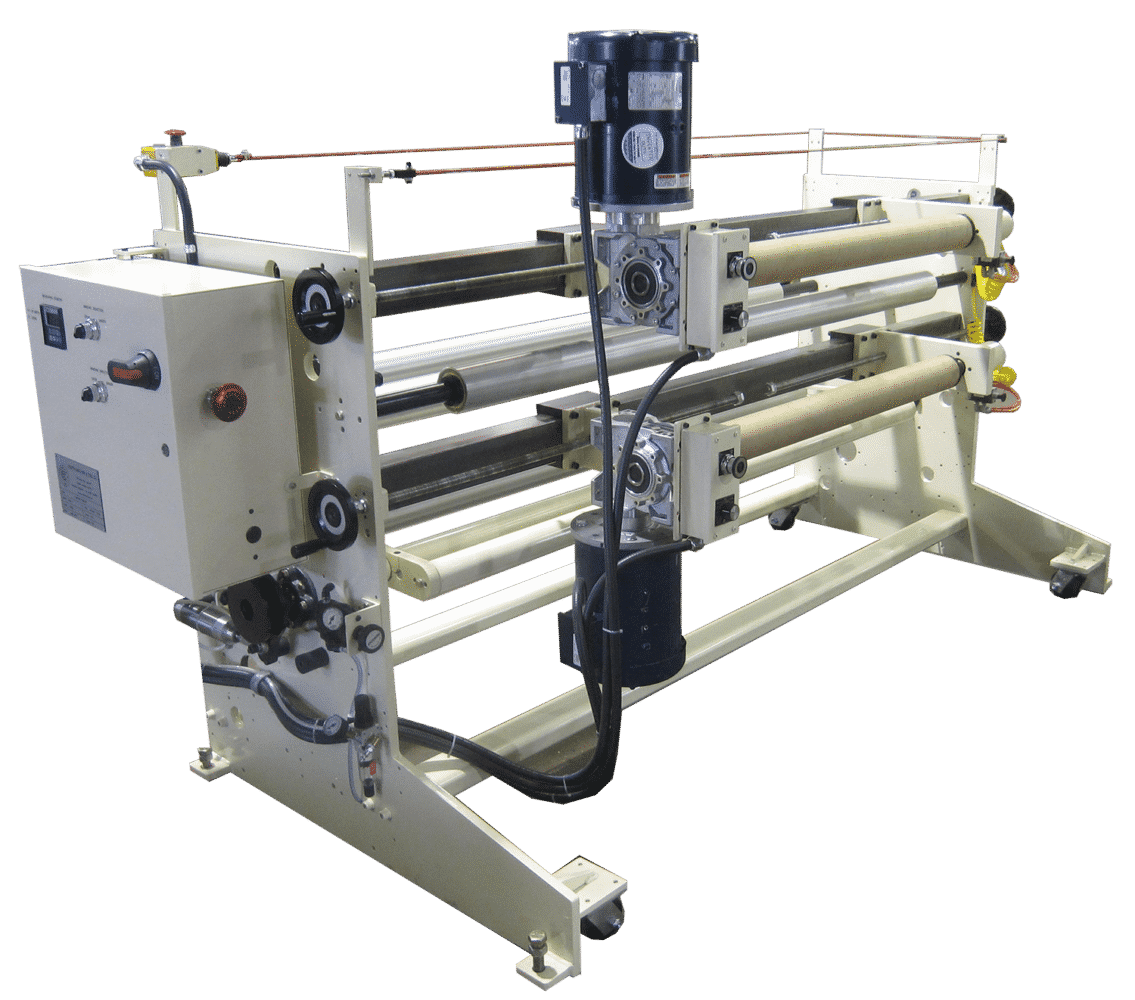

Surface Winder

The Surface Winder is a fully automated winding machine with a heavy duty build ideal for large diameter rolls. With a heavy duty motor, inline gear box, and a set of steel and rubber nip rollers, the surface winder operates up to 325 ft/min handling roll diameters up to 40” and 3000 lbs.

Turret Winder

The Turret Winder can wind perforated web up to 300 ft/min with 2 sets of air chucks that handle a 3” ID core up to 24” diameter rolls.

Unwinder

There are three types of unwinding machines available: The Power Roller Surface Unwinder; The Surface Unwinder with Air Shaft; and The Power Shaft Unwinder.

Folders & Separators

Our folder models can operate at upwards of 300 ft per minute using rollers precisely aligned to be parallel and square.

Our separators can separate bags or sheets at speeds of up to 300 ft/min. Modifications can be made to increase the operating speed to match the High Speed Folder version.

Bag Separator/Folder

There are three types of mini folders available: Standard Mini Folder; High Speed Folder; and High Speed 2-in-1 Separator/Folder.

Centre “V” Folder

With polished solid steel folding triangles and adjustable folding angles, the V folder can fold bags smoothly and precisely. The Centre V Folder has heavy duty side plates to handle continuous production demands.

Full Width Separator

The Full Width Separator up to 100” wide can separate bags or sheets at speeds of up to 300 ft/min with a corrugating nip and collecting table.

Other Solutions

We offer a Post Gussetter to form the gussetted pattern after the extrusion process, a Rotary Cutting Machine to make a rotating cut of any shape out of the bags, and other solutions.

Post Gussetter

The Post Gussetter is used to form the gussetted pattern after the extrusion process. This unit is up to 130” wide and stands up to 16’ high in 2 stations with a collapsing frame set and a gussetting board constructed from solid oak wood. With a Slit and Seal unit and additional gusseting boards, this machine is ideal for multiple lines with gussetting needs.

Rotary Cutting Machine

This machine can be used inline to make a rotating cut of any shape out of the bags. The Rotary Cutting Machine is ideal for t-shirt bags in a roll or individually folded.

Hole Punch

Hole Punch information.

Slitter

Slitter information.

Slit/Seal

SlitSeal information.